Gears

Heyy guys welcome back to my blog 😄, today I would be sharing with you my experience and what I have done for the Practical on Gears. Do read on as I would be sharing some wonderful and interesting pictures.

1. The definition of gear module, pitch circular diameter and the relationship between gear module, pitch circular diameter and the number of teeth.

2. The relationship between gear ratio (speed ratio)

3. How I can design a better hand-squeezed fan, including the sketches

4. How my practical team arranged the gears provided in the practical to raise the water bottle, consisting of:

a. Calculation of the gear ratio (speed ratio)

b. The photo of the actual gear layout.

c. Calculation of the number of revolutions required to rotate the crank handle

d. The video of the turning of the gears to lift the water bottle.

5. My Learning reflection on the gears activities.

1. These are the definition of gear module, pitch circular diameter and the relationship between gear module, pitch circular diameter and number of teeth:

The Gear Module refers to the size of the gear teeth. The unit for gear module is mm. The larger the module, the larger the size of the teeth. Gears mesh together have the same module.

The Pitch Circular Diameter is the imaginary circle that passes through the contact point between two meshing gears. It is the diameter of the two friction rollers in contact and moves at a linear velocity.

The Relationship between gear module (m), number of teeth (z) and pitch circular diameter (PCD).

PCD = m . z

PCD and m have a directly proportional relationship. As the gear module (m) increases, PCD increase as well.

PCD and z also have a directly proportional relationship. As the number of teeth (z) increases. PCD increases as well.

2. Below is the relationship between gear ratio (speed ratio) and output speed for a pair of gears.

The gear ratio is the ratio of the number of teeth in the driven gear to the ratio of the number of teeth in the driver gear.

Gear ratio is therefore the inversely related to the speed ratio of the gear.

When the gear ratio of increases the speed ratio decreases for a pair of gears.

Torque is calculated by using the formula of: T = F . d. Where Torque is (T), Force is (F) and Distance between the circumference and the centre is (d). Hence a larger gear ratio will lead to a larger output torque.

3. Below are the the proposed design to make the hand-squeezed fan better:

Initial Design

Therefore a proposed design was created as it was possible to make the fan run even more efficiently with at a faster speed. By increasing the size of input gear, it will increase the speed of gear output allowing the fan to rotate more rounds. Another way is to decrease the gear output which can also increase the speed of the output gear.

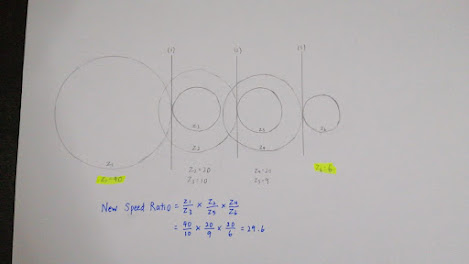

After making a few tweaks the design had a speed ratio of: This meant the theoretically each time the handle of the fan was cranked the turbine is able to rotate 29.6 times.

4. Below are the description on how my practical team arranged the gears provided in the practical to raise the water bottle.

We were tasked to lift a fully filled water bottle up for a distance of 20 cm. We wanted to archive a high output torque. As Gear Ratio = Output Torque / Input Torque, with a high gear ratio we will only need little input torque to produce a high output torque

- The photo of the actual gear layout.

- Calculation of the number of revolutions required to rotate the crank handle.

- The video of the turning of the gears to lift the water bottle.

5. Below is my Learning Reflection on the gears activities

Through this practical, I have learnt much more about gears and I honestly did not expect that there is so much to gears. Before the day of the practical, I browse through the worksheet and watched the four videos that was supposed to help us understand more about gears before the practical so that we wouldn't be very lost. I also looked through the work rest of the worksheet to get an idea of what we were going to do in this practical.

On the actual day, our teacher-in-charge Mr Chua sat us all down and told us that we were getting new teammates 😁. I was really excited as I wanted to get people I have not worked with before. After arranging us into groups by shuffling us using an online grouping generator, I ended up grouping with Aminur, Devin , Jiatong and Jihinn. He briefed us about gears and reenforced what we have learnt about gears from the 4 videos by teaching us on the whiteboard then it was time to do some work 😋. As time was not on our side our group decided that splitting the team into three was the best way around it. Jihinn was uncharge of completing the worksheet. Aminur and I were in charge of completing the water bottle challenge (activity 1). Devin and Jiatong were in charge of hand squeezed fan (activity 2). At first Aminur and I were struggling to even screw the gear onto the work board provided to each group but we picked up quickly afterwards. Soon we were doing trial and error to achieve the highest possible gear ratio. We eventually did it and achieved a gear ratio of 26.7 😳. By the look on Mr Chua's face, Aminur and I knew we had done a great job👍.

By the time we had recorded the video for activity 1, Devin and Jiatong also managed to finish their design. We were probably even one of the first groups to complete both activity with around 30 mins to spare. We then walked around to visit other groups and also offer them advise on how to do their design better.

All in all, practical about gears was extremely fun and I would definitely want to do such a practical in the future. I had many takeaways from this practical too like how to make the gear ratio bigger and how to use little force to lift heavy weight which can be quite useful for my capstone project in the future

Comments

Post a Comment